Wind Turbines Are Full of Sh*# and Flammable Lubricants

Lubed-up and ready to burn with 1400 L of synthetic oil and various greases

Tuco’s Child Preface

I was poking around in the literature and came accross a couple of articles that describe the large input of fossil fuels needed to construct and install wind turbines (1,2). These readings led me to another article that describes the high costs to remove and decommission wind turbines, the cost of which can exceed $500,000.00/turbine, believe it or not (!); and one can only imagine the costs of dismantling an offshore wind turbine on the high seas (!). There are a good number of articles that discuss the sky-high costs of decommissioning wind turbines, but apparently there is not alot of real world experience dealing with the avalanche of wind turbines now coming off service. The decommissioned turbines post disposal challenges because they are unweildy to deal with, contain volumes of synthetic lubricants to be disposed of, and generally lack recyclability, per below:

As most readers know, it’s ridiculously easy to find negatives about wind turbines, while in fact, it is difficult to find true positives, unless one has partaken of Green Kool-aid. To that end, I dug a little deeper into the bad juju and discovered that wind turbines require volumes of high tech specialty lubricants for electron generation and avian avarice, and that these materials have specifications and price points substantially over and above typical fossil fuel based fluids and lubes you might find at your local O’Reilly’s. The need for specialty synthetic lubricants is driven by the wind load demands, rotational forces and torque, shear forces, corrosion, and other potential failure modes.

Wind Turbine Lubrication and Better Living Through Chemistry. Don’t Worry, its Organic

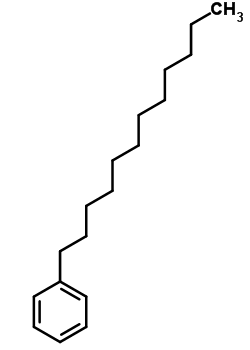

Benzene, mono-C10-14-alkyl derivs.

* Author’s disclosure: I am long XOM, DVN, ET

Wind turbines require large quantities of a variety of synthetic fossil fuel based specialty lubricants, especially the gearbox. After about 500 hours of operation, a wind turbine’s gearbox requires a “break-in oil change”, in which the Grande Muchacho may use up to 1400 L , or even more of spendy fluid.

After break-in, the fine tuned green machines get fresh dinosaur juice to lube up for more avian bludgeoning. After initially sopping up about 2800 L of super-trick gear oil, oil changes are only needed every 2-10 years depending on the generation of the wind turbine, size, and build specs.

All parts of a turbine require specialty lubricants, per Exxon:

“The most important ones are the main gearboxes, the main bearings, the pitch and yaw bearings, the generator bearings, the gears and the hydraulic systems. The main gear box has the highest demand for lubrication oil. Depending on the turbine size, that can be between 200 and 1,400 litres of lubricant. Each individual application point inside your turbine can have very particular requirements.”

It’s hassle to change wind turbine oil and expensive:

”The oil filter in the gearbox should also be changed after the first 500 hours of operation. After one year of operation, an oil sample should be taken to determine its viscosity, water content, acid number, contamination with particulate matter, and additive exhaustion. After two years, some recommend a complete oil change, even if its quality approximates the standards.

Periodic analysis of the oil is ideal because even a high-quality product is no guarantee of gearbox health. However, manually changing the oil is a challenging and time-consuming task. Workers lift and lower oil in special canisters using lifting devices (either elevators or ladders). This requires a team of three or four technicians and about eight hours of work time.”

Here is a video below showing how oil changes are performed:

It’s hassle to change wind turbine oil and expensive, especially at sea, but there is a Green Bonus, so not to worry:

Castrol has become the first lubricant supplier in the world to offer carbon-neutral lubricants for the wind turbine industry, CASTROL OPTIGEAR

“The huge growth in renewable energy has made a major contribution towards protecting the environment, but our customers are innovators and always looking at new ways they can reduce their carbon footprint and take further action on climate change,” said Daryl Luke, Global Product Manager at Castrol

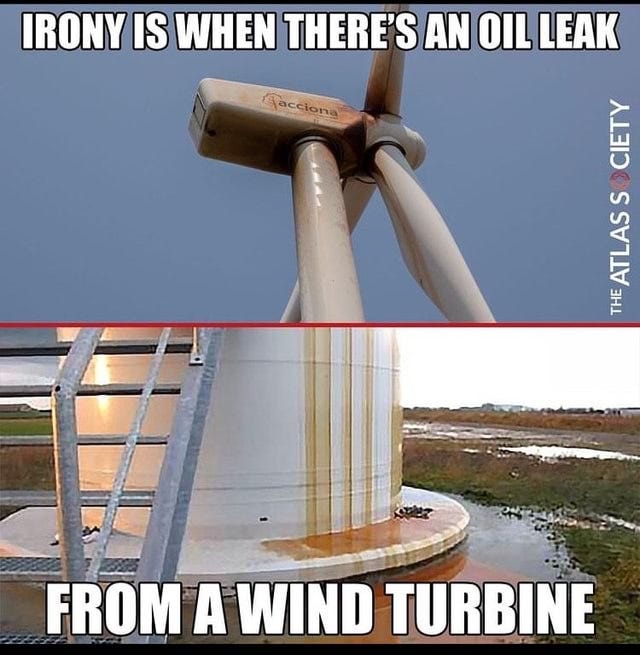

Oil leaks, oil slicks, and various conflagarations

Turbines leak oil and other lubricants due to seal, bearing, and gearbox failures. They also use hydraulic fluids in lines that may spring a leak due to fatigue, vibration, pinholes, or just by being made in China.

Turbines catch fire and burn quite readily as they are a reservoir of flammable fluids and greases. This fuel feeds the burning of the blades that are made from carbon based aromatic resins (epoxies) that in turn spew out massive plumes of carcinogens such as benzene and methyl-ethyl-propyl bad-shit and toxic particulates.

Lightening strikes and other acts of god can lead to the spewing Roman Candle Turbine effect, in addition to sparking-off by internal mechanical failures. The fires are hard to stop once they get going, and may require a helicoptor or airplane to help put it out or just retard the fire. Not as bad as runaway lithium battery fires, but still a royal PITA!

A real serious negative of wind turbine fires is that they can cause brush and forest fires and millions in damage, some of which is reviewed here.

Lets not forget that a torched turbine will cost a pretty penny to decommission and scrap, likely costing several hundred thousand dollars and involving plenty of fossil fuel consumption along the way.

Imagine how environmentally filthy this technology would be if it weren't labeled as "green." It seems like a very expensive way to kill millions of birds .......

I'm off to get chainsaw parts, in my F250 Powerstroke Diesel.

I was reading an article about how Hawaii doesn’t like these wind turbines! They have fields of grease from the turbine! But I really like that dinosaur juice jargon, you nailed it!