Dump Run: Wind Turbine Blade Waste to Exceed 43 Million Tons/yr by 2050

Dump, Burn or Recycle ? Construction Fillers, Fuel, Playgound Structures, and Sculptures

Introduction: Massive Quantities of Waste Blades with Nowhere to Go

In about 10-20 years, the wind turbines put into operation today will be nearing the end of their lifespan, or so they say. In reality, the actual lifespan of the fiberglass and resin blades can be shorter than 20 years, because the lifespan is highly dependent on the external environment they operate in, as well as the manufacturer quality control.

For example, certain manufacturers have struggled with quality control, many of which are China based, and sell less expensive products propped up by government subsidies.

Back to the present, for those wind turbines have been around for at least 20 years, we are now facing a enormous disposal problem. Blades are are a tough fiberglass composite like those found in many products from surfboards to boats, and are thus extremely difficult to recycle, due to their composition and because they were designed to be durable and withstand harsh weather,

As materials chemist having worked with composites and epoxy resins, I can assure the reader that any recycling solution is a big net loser, from cradle to grave. This is simply because each step, from dismantling to transport to processing and to product delivery requires a significant input of fossil fuels and energy; but perhaps most importantly, commodity fiberglass (SiO2 or silica) and epoxy resins which comprises a blade are “cheap as dirt”, so recycling to obtain these products in some way shape or form makes little economic sense without subsidies or tax breaks etc. Any scheme should be looked at in terms of real costs and energy input and output, not green Excel spreadsheets propped up actually propped up by taxpayer subsidies.

Wind turbine blade failures and wear can be classified into the following four categories:

damage from lightning

failures due to fatigue

leading edge erosion

damage from icing

The scale of the recycling problem is large and growing. The cumulative mass of decommissioned blades in the US will reach 1.5 million metric tons (t) by 2040 and 2.2 million t by 2050, according to a recently published study by Aubryn Cooperman, a wind energy analyst at the National Renewable Energy Laboratory (NREL), and coworkers (Resour., Conserv. Recycl. 2021, DOI: 10.1016/j.resconrec.2021.105439).

Globally, the mass of all the blades expected to be retired by 2050 may be as high as 43 million t, according to a study led by Barlow (Waste Manage. 2017, DOI: 10.1016/j.wasman.2017.02.007). The 2017 study published in the scientific journal Waste Management, the world’s wind industry will be producing 43 million tons of blade waste annually by 2050. The U.S. and Europe will account for 41% of that.

Logistics: Huge Turbine Blades are Difficult to Transport and Recycle

As noted, blades are difficult to recycle because they were designed to be durable and withstand high winds and harsh weather for 20-plus years. They’re are also huge-some reach 95 m in length or longer—and often located in remote places, making transportation logistically challenging and expensive, typically hauled by diesel trucks. The size and weight of the blades vary, but the average length is around 120 feet and they weigh around five tons. Some of the largest can be as long as a football field and weigh 20 tons.

Blades are Made from Tough Composite Materials and Cannot Be Melted or Dissolved

Cut ‘em up: large saws cut wind turbine blades into smaller sections before heading to the shredder for “recycling”

Composites are difficult to recycle because they comprise of variety of chemically bonded and are thus difficult to separate thus recycled. Blade composition varies by manufacturer, but typically 80–90% of the mass of the blade is a composite material. Sixty percent to 70% of the mass of the composite consists of reinforcing fibers—mainly fiberglass plus some carbon fiber. The balance is a polymeric resin that bonds the long, stiff fibers in a rigid, relatively lightweight solid matrix. The combination of inorganic long glass fibers and a hard crosslinked thermoset resin, such as an epoxy, makes blades especially difficult to recycle. This is because cured resins form strong cross-linked networks that lock the reinforcing fibers in place and are thus by design, difficult to break down. They can’t be melted or flowed like thermoplastics or dissolved, because the matrix is cross-linked together. Currently, there are no scalable, cost-effective technologies to recycle the blades, and most of them are going to landfills.

One company, Siemans Gamesa, which dubs itself as "the global leader in offshore power generation”, and lost a staggaring 1 Billion US on it’s wind turbine business associated with turbine failures in 1 quarter and is in deep financial trouble, claims to have a new recyclable resin and blade. As a chemist, I say good luck dealing with the huge blades and dissolving them. I guarantee it is a big net loser. Just chop and cleanly burn, not worth the trouble. Better yet, terminate wind power projects worldwide and put the money into safe nuclear!

“Repurposed” Recycled Blades: Fossil Fuel Intensive Processing and Burning For Fuel

Shredded blades for use as a filler in road pavement, cement, plastics, or just burned to power industrial processes- all fossil fuel based processing and materials

Playground Playtime for Euro-Kiddies

Bike Shelters in “Sustainable” Denmark

Wind Turbine Blade Sculptures

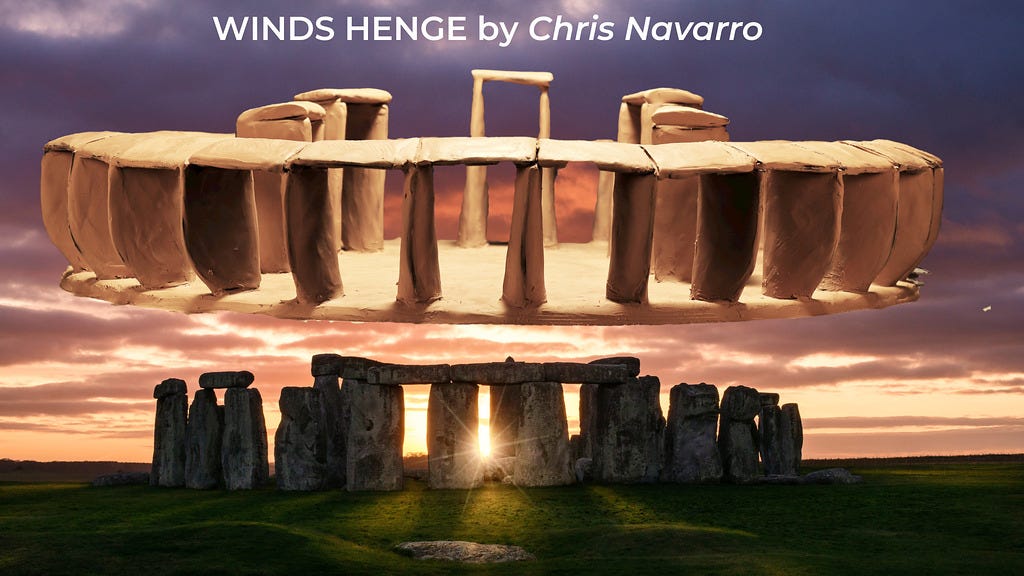

For the fair price of $5,900.00, ‘’WINDS HENGE’’ would repurpose 40 obsolete wind turbine blades into a representational sculpture designed after the famous Stonehenge. The 5000-year-old prehistoric monument in Wiltshire, England.

The design uses obsolete wind turbine blades and cutting the long blades into sections and setting them in an outer ring of 30 columns at a height of 15’ with the 5 internal columns height 25’ in a 108’ diameter.

According to Cowboy State Daily, Chris Navarro, a Casper Wyoming artist, is trying to repurpose blades for public sculptures. He’s currently working with a wind turbine company to get the blades shipped from Sidney, Nebraska. “We’re trying to get a bid to get the blades cut to the specifications we want and get them shipped to Casper. That’s my next hurdle,” Navarro told Cowboy State Daily.

He currently has a cutting order for about 45 blades, which won’t make much of a dent in the amount of waste the blades will be generating in the coming years. But Navarro said when he saw the photos of the blades being disposed of in the Casper Landfill, he wanted to find a way to help address the problem through his art.

So @ 167 thousand tons to build a 1.1GWe Nuclear Power plant that means 43e6 tons/167e3=257 NPPs could be built with the same amount material in discarded Wind Turbine blades every year. That's just the blades which are just a small portion of the total Wind Turbine mass. So in 12yrs you would have enough NPPs to supply all the World's electricity needs, rather than giant heaps of wind turbine blades.

And each NPP will last 60-100yrs, not the 10-20yrs the Wind Turbine lasts.