Part 1: Fossil Fuels Create 1 Trillion Computer Chips per Year

The most complex devices ever created by mankind depend on burning fossil fuels

Above: an Intel i9 central processing unit (CPU) contains cores or chips that work simultaneously together.

Introduction

Every aspect of our modern society depends on silicon based semiconductor chips such as microprocessors, memory chips and graphics chips. The production of chips is critically dependent on fossil fuels and the combustion of carbon, not just due to the power and ultra high purity consumables needed for manufacture, but also due to the physics and chemistry of the device materials and the device itself.

Tuco’s Child comment: “there is no such thing as sustainable or renewable, only changes and hopefully improvements in efficiencies. There is always an input and an output in any process that must be measurable.”

Chips comprise billions of transistors (gates or on-off switches) which make chips the most complex devices ever created by man. Not only are chips extremely complex, they contain very few inherent defects, which means that they have low entropy or disorder. This is a critical concept, as low defects in chips (low defect density) yield the most efficient chip operation, highest yields and highest profits. In contrast, if the defect density is too high, the chip or core may not function properly, and may be discarded or downgraded, thus decreasing yield and profits.

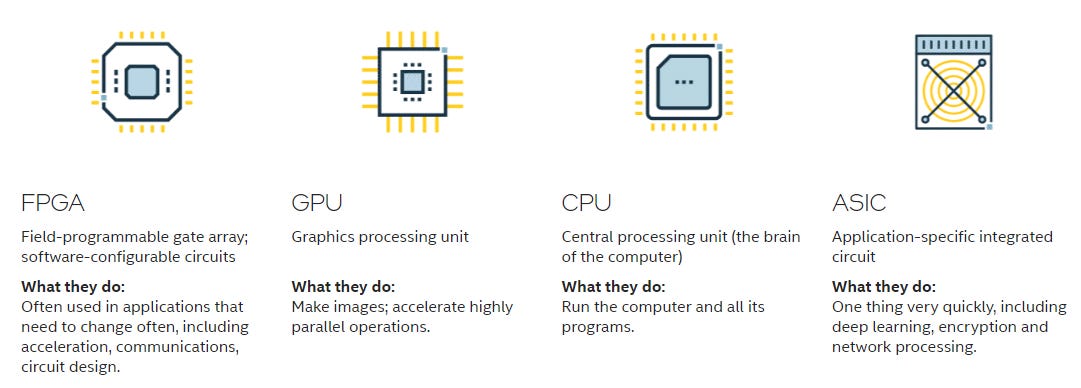

There are many different types of chips manufactured, with 4 popular types shown below:

From Intel: 4 popular chip types - programmable, graphics, cpu, and app specific

It would be difficult to list every aspect of our society that depends on computing power. Per below, the 2022 global chip market was valued at $574 billion, and is still dominated by the consumer PC/computer market.

Above from SIA.

Remarkably, in 2021, the Semiconductor Industry Association (SIA) announced that global semiconductor industry shipped over 1 trillion semiconductor units, as chip companies ramped up production to address high demand amid a global chip shortage.

From Statistica and SIA: over 1 trillion chips were sold in 2021 and sales continue to increase.

Given the worldwide dependence on computer chips, it is worthwhile to explore the critical role of fossil fuels in enabling our modern day computing life, starting with the production of pure silicon from silica or sand.

In a previous article, we described the fossil fuel and carbon intensive production of pure silicon, the main material or chemical element from which chips are made. That article describes in detail the production of pure silicon, which critically depends on coal, oil, and wood products. Production of pure silicon requires a large input of energy to “reduce” silica (SiO2) to silicon, which is then sliced into wafers suitable for computer chip manufacturing.

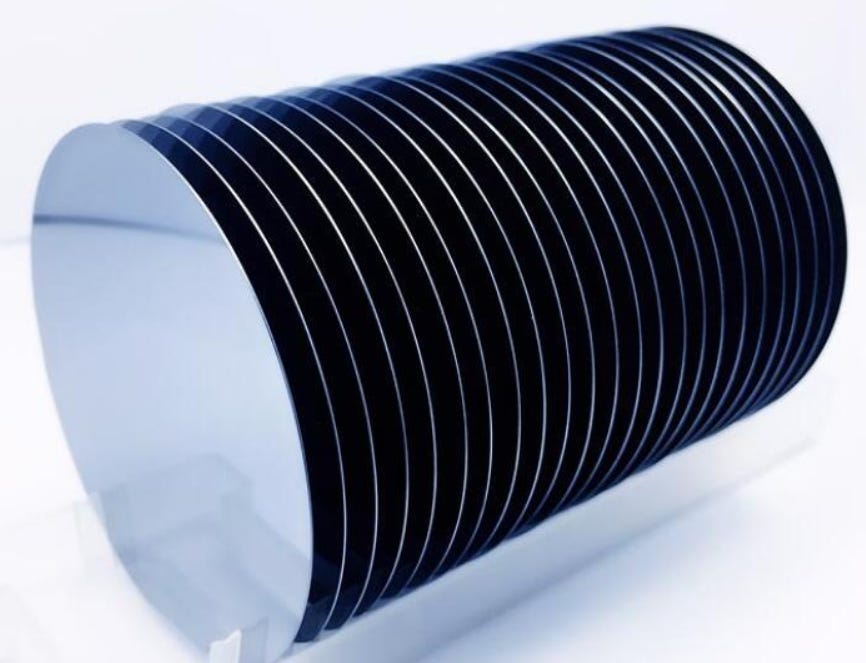

Above: a tray of pure 12“ silicon wafers suitable for computer chip manufacturing.

The silicon wafers as shown above serve as the substrate from which computer chips are made, in which the wafers are subjected to hundreds of processing steps in an ultra-clean and air conditioned chip fabrication plant (fab).

The most complex devices ever created by mankind depend on burning fossil fuels

This article, part 1 of 2 parts, serves as an overview of the fossil fuel intensive processes used to make semiconductor chips, and illustrates the need for fossil fuels to make highly ordered and complex computer chips. To start, it takes hundreds of individual processing steps in a semiconductor chip fab to produce a functioning integrated circuit or chip. Intel (cpu) has published good broad overview video below:

Video above showing how highly ordered chips are created in a world that tends towards disorder

We burn fossil fuels to do work to order everything in our modern world. By burning fossil fuels, we liberate potential energy to do work and oxidize ordered oil and coal materials. Oxidation or combustion creates a large number of disordered molecules and waste heat; most commonly gaseous CO2 and water vapor.

Low defect objects or devices such as microprocessors or semiconductor chips can be thought of as low entropy or low disorder devices. Entropy can be interpreted as a measure of order and/or disorder in a system. In our physical world, things tend towards disorder and then reach a resting state or an equilibrium state. The tendency for things to disorder vs order is described by the Second Law of Thermodynamics.

Tuco’s Child comment: “Fossil fuels are irreversibly burned to do some work and create highly complex low entropy devices called semiconductor chips. Essentially, the trade-off is a highly complex low defect chip in exchange for waste heat and more disorder in the world.”

Above: defect testing individual computer chips (dies) on a wafer. After a wafer is mapped, bad chips are launched and good in spec chips are kept. The defect density for a wafer is calculated by measuring number of defects over an area in x, y.

Above: in-spec or good chips are carefully removed by dicing up a wafer. After dicing, the good chips are sent for packaging. If a chip has too many defects, it may be thrown away or downgraded and resold.

Running a fossil fuel intensive semiconductor fab

A semiconductor chip factory, or “fab,” is a manufacturing and engineering marvel that costs $10 to 15 billion dollars to build, and takes approximately three to five years and 6,000 construction workers to complete.

Above: the TSMC fab in Taiwan makes 90 % of the high end microprocessors in the world and consumes massive amounts of electricity.

Every hour, every day, a fab produces many thousands of computer chips, the most complex products on Earth and each not much bigger than a fingernail. Energy is consumed 24 x 7 to run a fab that comprises many tens of thousands of sq ft of active floor space and support facilities, on multiple levels or stories. To maintain the production of low defect chips, the fabs must stay running in some form or another 24 x 7 to maintain the proper consistent conditions for making chips. For example, fabs contain many types of finicky and expensive processing tools or machines that must be constantly maintained and fed consumables so that they can run a vetted ”process of record” to make chips. A typical fab contains about 1,200 multi-million-dollar process tools and 1,500 pieces of utility and support equipment.

Above: fab floor with process tools

Almost all equipment and active processing is performed in temperature and humidity controlled clean rooms, and other particle free scrubbed environments. One tiny particle or chemical contaminant can ruin a chip. An Intel video below gives the reader an idea about what it is like in a fab:

Above video gives a good walk-through of a fab

Chip manufacturing also requires large quantities of ultra-pure water, cool air, process gases, and specialty chemicals; as well as special care and handling of toxic and hazardous materials and waste products. Additionally, chip processing yields are not 100 % by any means, and there are a variety of waste materials to dispose of. In any case, enormous amounts of energy, water, chemicals and other materials are needed to create chips.

Energy Consumption at Intel’s Ocotillo Chip Fab in Chandler, AZ

Intel’s Ocotillo campus, which covers approximately 700 acres of land in the City of Chandler, is an important part of Intel’s global technology manufacturing network.

From Intel: “Intel established a presence in Arizona in 1979 and began operations in Chandler the following year. Today, with 10,000 employees across two Arizona campuses, Intel develops and manufactures microprocessors that power data centers and hundreds of millions of smart and connected devices worldwide.”

Above: Intel’s quarterly energy consumption at the Ocotillo Campus in 2023 was approximately 500,000 kWh/quarter.

Fossil fuel consumption at Ocotillo derived from Intel Data

In the last quarter of 2023, the Ocotillo fab energy consumption was 522,331,178 kWh and was obtained from electricity, natural gas and fuel oil. That is a staggering 2,089,324,712 kWh in 1 year (4 quarters).

However, the Ocotillo fab energy mix comprises about 55 % of direct burning of fossil fuels according to Arizona State Energy Profile.

Adjusting for the Arizona State Energy Profile of about 55 % for direct burning of fossil fuels, the yearly number estimate for the Intel fab is about 1,149,128,592 kWh, which is a mindblowing 675958 boe/year, not including the indirect burning of fossil fuels from other energy sources in the mix, which are buried in the numbers not counted here.

I will take a SWAG (scientific wild ass guess) and say that if a proper life cycle analysis was conducted for all the energy sources, the total fossil fuel burn at the Intel fab is closer to 75 %. One energy source possibly keeping it from 100 % fossil is the use of nuclear energy in the mix, which has the highest EROI and energy density due to E=mc^2. The nuclear energy portion of the mix in AZ is about 29 %.

Let’s do a Gedankenexperiment or thought experiment for a sec. Given the above SWAG, lets round up the 675958 barrel of oil equivalent that Intel’s fab sucks down to an even 1 million boe. That 1 million barrels is about half the capacity of a Very Large Crude Carrier (VLCC) Supertanker. Would’nt it be more efficient to park a small nuclear reactor (SMR) at that fab?

Question. What percentage of total AZ energy does Intel’s fab consume? In a rough estimate, taking the yearly 2,089,324,712 kWh/year energy consumed per Intel, we get about 7.1 trillion btu. In 2021, AZ produced 500 trillion btu of energy. So Intel consumes roughly 1.4 % of AZ total energy output, likely an underestimate. My SWAG is probably closer to 2 %.

Part 1 Summary and Part 2 Preview

To obtain pure silicon wafers suitable for computer chip manufacturing, large amounts of fossil fuels and wood products are consumed as described in Burning Coal and Trees to Make Computer Chips and Solar Panels. After the silicon wafers are obtained, there are hundreds of process steps in a specialized fab to create a chip. Over 1 trillion chips per year are now made and sold globally

Tremendous amounts of energy are needed 24 x 7 to run a chip fab. We have estimated that Intel Ocotillo directly burns fossil fuels to the tune of 675958 boe/year, and consumes roughly 1-2 % of the total energy produced in AZ/year.

In Part 2 we will drill down further and present some astonishing numbers regarding the barrels of oil equivalent needed to produce 1 trillion chips a year, using an Intel fab and other sources to back out those numbers. In preview, one study has estimated the mass of fossil fuel and chemical inputs needed to produce one 2 gram microchip. The study found that to make one 2 gram memory chip, it takes 1.7 kg of fossil fuels and 72 grams of chemical input.

This inordinately large input of fossil fuel mass is due to the complexity and low defectivity of the semiconductor chip. The table below shows a comparison of the mass of fossil fuels needed to make a chip in comparison to a car or a refrigerator, which are relatively simple items. Note that for the chip, the ratio of the mass of fossil fuels used/mass of product is massive compared to the other more mundane products.

Bonus News Flash: AZ backs off from “renewables” mandate. How ya gonna run a chip fab using wind and solar energy, right?

AND

Bonus AZ Nuclear Power Note from Van Snyder

Phoenix is powered by the Palo Verde nuclear generating station, about 50 miles west on 4,000 acres with three reactors cooled by waste water, producing 3.8 GWe. It's the largest nuclear power station in the country, and the only one in a desert. It was built for $3.79/watt, and remains one of the most profitable utilities in the country (if you don't count subsidies for solar and wind). Why did Vogtle cost $13.75 per watt? How is China building the same design of nuclear power stations for $2.75/watt? Ask the NRC and Sierra Club and Friends of the Earth and ....

This newsletter is for all my followers, subscribers, new readers and for Stern Dr. Jeffrey Bonanno, x-ray crystallographer extraordinare.

A very good read! Thank you for the research!

Thank you. Very interesting. Good reason to try to protect Taiwan from the CCP. Isn’t the same wafer technology used in the production of solar panels?

I propose that all leftists and climate change whackos agree to stop using any item involving chip technology.