Fossil Fuels Create 1 Trillion+ Computer Chips per Year

Semiconductor chips are the most complex devices ever created by Humankind

Above: an Intel i9 processer contains cores that work simultaneously together.

Introduction

Every aspect of our modern society depends on silicon based semiconductor chips such as microprocessors, memory chips and graphics chips. Chips comprise of billions of transistors (gates or on-off switches) which make chips the most ordered devices ever created by Humankind.

Chips have very few defects, which means that they have low entropy or disorder. This is critical because low defect chips yield the most efficient chip operation and highest profits. In contrast, if the defect density is too high, the chip or core may not function properly, and may be discarded or downgraded, thus decreasing profits.

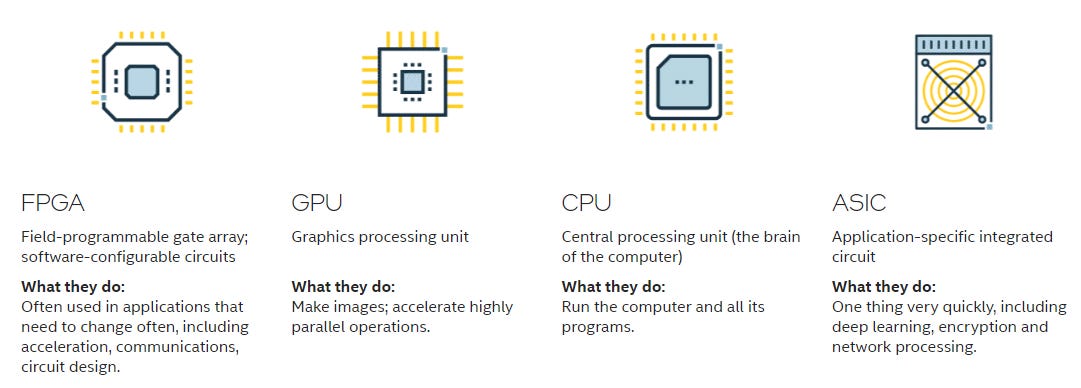

There are many different types of chips manufactured, with 4 popular types shown below:

From Intel: 4 popular chip types - programmable, graphics, cpu, and app specific

Per below, the 2022 global chip market was valued at $574 billion, and is dominated by the consumer PC/computer market. Remarkably, in 2021, the Semiconductor Industry Association (SIA) announced that global semiconductor industry shipped over 1 trillion semiconductor units.

From Statistica and SIA: over 1 trillion chips were sold in 2021 and sales continue to increase.

Fossil fuels play a central role in enabling our modern day computing life, starting with the production of pure silicon from silica (SiO2).

In a previous article, we described the fossil fuel and carbon intensive production of ultra-pure silicon, the main chemical element from which chips are made.

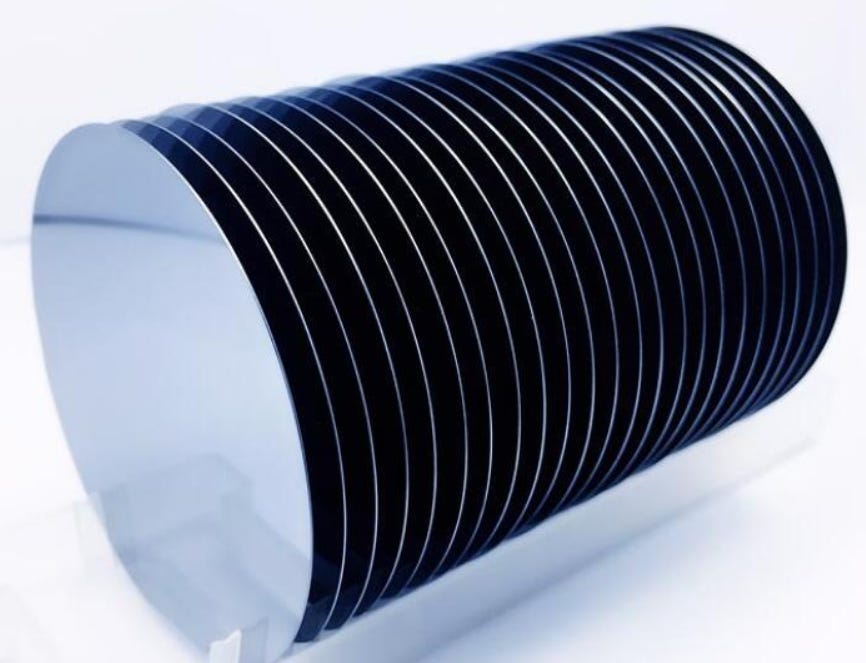

The production of pure silicon critically depends on coal, oil, and wood products, and requires a large input of energy to “reduce” silica (SiO2) to silicon (Si). The ultra-pure silicon ingots thus obtained are then sliced into wafers suitable for computer chip manufacturing.

Above: a tray of ultra-pure 12“ silicon wafers.

Tuco’s Child comment: “most processes are irreversible, so there is no such thing as sustainable or renewable, only changes in efficiency.”

Fossil Fuels Enable the Most Complex Devices

Chip production is critically dependent on fossil fuels because of:

The carbon needed in the production of ultra-pure silicon wafers.

The high energy demands of the chip manufacturing processes and the chip fab.

The critical need for ultra high purity materials and consumables to make a chip.

The physics and chemistry of the device materials and the device architecture.

There are hundreds of individual processing steps to produce a functioning integrated circuit or chip. Intel has published a useful overview video below:

Video above showing how highly ordered chips are created in a world that tends towards disorder.

Ordered and low defect devices such as microprocessors or computer chips are low entropy or low disorder devices. Entropy can be interpreted as a measure of order and/or disorder in a system. In our physical world, things tend towards disorder and then may reach a resting state or an equilibrium state. The tendency for things to disorder vs order is described by the Second Law of Thermodynamics.

Above: defect testing individual computer chips (dies) on a wafer. After a wafer is mapped, bad chips are launched and good in spec chips are kept. The defect density for a wafer is calculated by measuring number of defects over an area in x, y.

Tuco’s Child comment: “Fossil fuels are irreversibly burned to do some work and create highly complex low entropy semiconductor chips. The creation of highly ordered chips results in more disorder in the world”.

Running a Fossil Fuel Intensive Semiconductor Fab

A semiconductor chip factory, or “fab,” is a manufacturing and engineering marvel that costs $10 to 15 billion dollars to build, and takes approximately three to five years and 6,000 construction workers to complete.

Above: the TSMC fab in Taiwan makes 90 % of the high end microprocessors in the world and consumes massive amounts of electricity.

Every hour, every day, a fab produces many thousands of computer chips, the most complex products on Earth and each not much bigger than a fingernail. Energy is consumed 24 x 7 to run a fab that comprises many tens of thousands of sq ft of active floor space and support facilities, on multiple levels or stories. To maintain the production of low defect chips, the fabs must stay running in some form or another 24 x 7 to maintain the proper consistent conditions for making chips.

Fabs contain many types of finicky and expensive processing tools or machines that must be constantly maintained and fed ultra-pure chemical consumables so that they can run a vetted ”process of record” to make chips. A typical fab contains about 1,200 multi-million-dollar process tools and 1,500 pieces of utility and support equipment.

Above: fab floor with process tools.

Almost all equipment and active processing is performed in temperature and humidity controlled clean rooms, and other particle free scrubbed environments. One tiny particle or chemical contaminant can ruin a chip. An Intel video below gives the reader an idea about what it is like in a fab:

Above video gives a good walk-through of a chip fab.

Chip manufacturing also requires large quantities of ultra-pure water, cool air, process gases, and specialty chemicals; as well as the special care and handling of toxic and hazardous materials and waste products.

Chip processing yields are not 100 % by any means, and there are a variety of waste materials to dispose of. In any case, enormous amounts of energy, water, chemicals and other materials are needed to create chips.

Large Quantities of Fossil Fuels and Materials are Used to Make One Tiny Chip

A study has estimated the mass of fossil fuel and chemical inputs needed to produce one 2 gram microchip. The study found that to make one 2 gram memory chip, it takes 1.7 kg of fossil fuels and 72 grams of chemical input.

This inordinately large input of fossil fuel mass is due to the complexity and low defectivity of the semiconductor chip, and inefficiencies in the manufacturing processes.

The table below shows a comparison of the mass of fossil fuels needed to make a chip in comparison to a car or a refrigerator, which are relatively simple items.

Note that for the chip, the ratio of the mass of fossil fuels used/mass of product is massive compared to the other more mundane products.

Fossil Fuel and Energy Consumption at Intel’s Ocotillo Fab

Intel’s 700 acre Ocotillo campus in AZ.

Energy Consumption at Ocotillo

Above: Intel’s quarterly energy consumption at the Ocotillo Campus in 2023 was approximately 500,000 kWh/quarter.

Per Intel data, the annual Ocatillo fossil fuel consumption equates to about 1,149,128,592 kWh, or about 675958 boe/year, adjusting for AZ energy mix.

Above: a Very Large Crude Carrier (VLCC) has the capacity to supply Intel’s Ocatillo fab annual needs of about 700,000 barrels of oil.

Key Points and Calculations re. Intel Energy Consumption and AZ Power Mix

In the last quarter of 2023, the Ocotillo fab energy consumption was 522,331,178 kWh and was obtained from electricity, natural gas and fuel oil. That is a staggering 2,089,324,712 kWh in 1 year (4 quarters).

The Ocotillo fab energy mix comprises about 55 % of direct burning of fossil fuels according to Arizona State Energy Profile.

The annual Intel Fab fossil fuel consumption equates to about 1,149,128,592 kWh, a mindblowing 675958 boe/year, not including the indirect burning of fossil fuels from other energy sources in the mix.

I will take a SWAG (scientific wild ass guess) and say that if a proper life cycle analysis was conducted for all the energy sources, the total fossil fuel burn at the Intel fab is closer to 65 % vs. vs. 55 %.

Much power is derived from the Palo Verde nuclear plant, the largest in the USA. The nuclear energy portion of the AZ power mix is about 29 %.

Intel consumes roughly 1.4 % of AZ total energy output, likely an underestimate. Intel consumes about 2,089,324,712 kWh/year (roughly 7.1 trillion btu). In 2021, the State of AZ produced 500 trillion btu of energy.

Tuco’s Child comment: “ I contacted Intel and others to find out how many chips per year are produced at Ocatillo. I was repeatably told that the information is confidential”

Conclusions

Semiconductor chips are the most ordered and sophisticated low entropy devices ever created. To produce a chip, large amounts of disorder are created, per the Second Law. From ultra-pure silicon wafers, over 1 trillion chips per year are made and sold globally. Hundreds of process steps in a specialized fab must be performed to create a chip.

To create a tiny 2 gram memory chip, at least 2 kgs of fossil fuels and other materials are consumed. I surmise more materials are used to create CPUs and graphics chips which are more sophisticated.

Tremendous amounts of energy are needed 24 x 7 to run a chip fab. We have estimated that Intel Ocotillo directly burns fossil fuels to the tune of 675958 boe/year, and consumes roughly 1-2 % of the total energy produced in AZ/year. A VLCC oil tanker is needed to transport this amount of oil.

Sidenote: AZ Nuclear Power

Phoenix is powered by the Palo Verde nuclear generating station, about 50 miles west on 4,000 acres with three reactors cooled by waste water, producing 3.8 GWe. It's the largest nuclear power station in the country, and the only one in a desert. It was built for $3.79/watt, and remains one of the most profitable utilities in the country.

Above is the Palo Verde nuclear generating station.

This newsletter is for all my followers, subscribers, new readers and for Stern Dr. Jeffrey Bonanno, x-ray crystallographer extraordinare, and my other buddy from graduate school, Dr. Elder, who recently bid Intel sayonara! Further kudos to Dr. Fantini, at Denison U., still churning out molecules and teaching the kids.

I’m still waiting for a solar-powered solar panel factory. And a solar-powered tractor for quartz crystal mining.

Excellent write-up, thanks. alas, those in the climate religion believe what they want to believe even as they use the products that require fossil fuels to be created.